CONVEYOR BELTS for industrial use

The metal spiral mesh play a fundamental role in modern chain conveying systems. They have an open mesh that allows for the circulation of air or gas, allowing for the easy drainage of any washing or manufacturing liquids. Their structure is also suited for drying processes, such as pasta or other food products.

FURNACES

WASHING PLANTS

DRIERS

TRANSPORT

COOLING PLANTS

The most recognised characteristic of these metal belts, made with mesh of different shapes and with steel wires and straps, is their great reliability over time with demonstrated wear resistance, as well as the ability to work at high operating temperatures (up to 1200°C) in the presence of considerable mechanical stress also in aggressive environments or with the passage of process lubricants.

Our stainless steel or iron conveyor belts are usually important components in plants for the horizontal handling of goods and are wisely used in metallurgical, food, mechanical and chemical applications, in the pharmaceutical industry and also in the ceramics and glass industry.

Types of conveyor belts

Edges of belts

Technical info

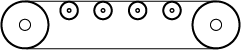

The conveyor belts we produce, with the exclusion of the grecato type, which is driven by toothed cog wheels, are mounted on two rollers, one is fixed for traction and the other is mobile for adjustment, at idle (see figure). It is recommended to use rollers without a lateral flange, in particular cases they can be mounted on chains. To guarantee a long service life, the belt must be mounted correctly.

The rollers must have the largest diameter possible (considering that driving takes place by means of friction in the point of contact of the driving roller) and in any case the diameter may not be less than 10 times the pitch of the rod. If the belt slips on the roller, this problem may be solved with the following measures (individually or in combination): – Increase the diameter of the driving drum – Cover the drum with material that has a higher friction coefficient (rubber, knurling, …) – Increase the winding arc of the belt on the drive drum, using a tensioner (see figure)

To support the conveyor belt, and only for plants that run at a slow speed, the belt can be supported by structural angle bars, possibly covered with material that has a low friction coefficient (wear resistant), which can be metallic (iron, steel, manganese) for applications at high temperatures, or plastic (Polizene® for temperatures up to 70°C, PTFE up to 200°C). The angle bars can be placed parallel to the length of the belt (see figure).

If greater flatness is required and if the product to be transported is very heavy, the angle bars must be positioned in a “fishbone” pattern, proportioning their distances based on the weight and dimensions of the material to be transported (see figure)

If the weight and flatness are preponderant factors, support rollers must be used (see figure)

Made in Italy

Made in Italy